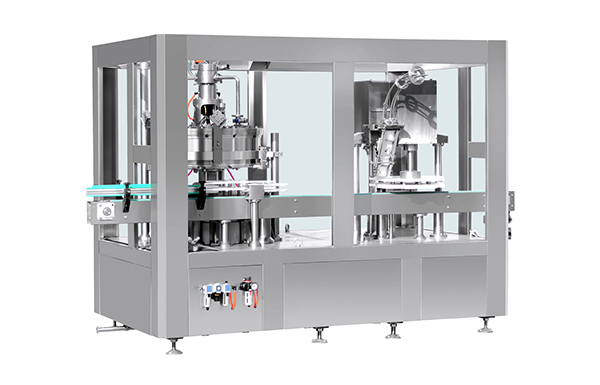

The filling machine has applications in many industries and is an indispensable equipment in many processing enterprises, such as food, beverage, medicine, and daily chemical production and processing enterprises. However, most people don't know how to use and maintain the filling machine. The following are some usage methods and maintenance tips for the filling machine:

Now people's demand for various beverages and daily-use chemical products has increased, which has also played a certain role in promoting the development of filling machines. Filling machines are widely used in production, and the installation, commissioning and operation of filling machines And maintenance work is very important.

First of all, before using the filling machine, we must first install and debug, read the manual carefully before commissioning, and prepare to use the tool. After installing the filling machine, transfer the filling rail and the bottle connection plate to a horizontal level, and fill the storage tank with material. Put the container in the tool box and turn on the external power supply. The power socket must be installed as a tripod socket and be reliably grounded to prevent leakage into the cabinet. Turn the power switch to ON and the power indicator light on. The filling frame is supported with a filling frame support plate, pointing to the top of the movable filling head positioning sleeve. The positioning sleeve should move flexibly up and down, where the filling needle is exposed or retracted without hindrance. The switch under the storage tank is moved to the open position so that the material can flow into the total metering pump. According to the filling amount of each container, the screw of the crank is adjusted, and the filling speed of the knob plate is 20 degrees, and then the switch is quickly dialed To the open position. For each oil injection head, when the liquid volume adjustment nut is set, cover the oil injection head shell and loosen the oil injection frame support plate.

After the filling machine is used, attention should be paid to its maintenance. Before cleaning the piston filling machine, the remaining products should be cleaned first, and then filled with a soft cleaning solution. The cylinder has been added with grease before leaving the factory. Please do not open or add any lubricant to ensure that the surface of the filling machine is clean and do not work when the power is off. In addition, while insisting on maintenance and correct use of the filling machine, regular testing and commissioning are also required. Only in this way can the machine work stably and healthily.

简体中文

简体中文 English

English