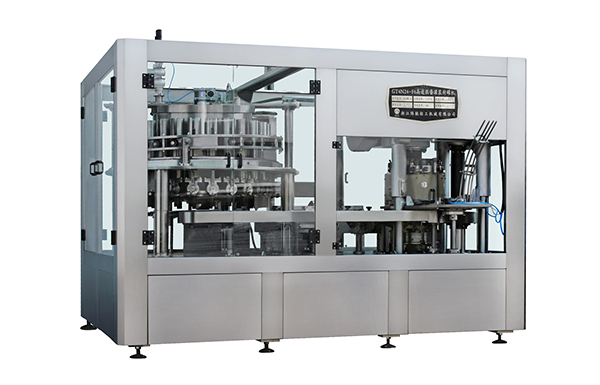

The method of maintaining the parts of the liquor filling machine:

1. Before starting the liquor filling machine, you must use the shake handle to turn the machine to check if there is any abnormality in the rotation, and then drive it normally.

2. When adjusting the machine, use appropriate tools.aluminum can seamer It is strictly forbidden to use excessive tools or excessive force to disassemble parts to avoid damage to the machine parts or affect the performance of the machine.

3. After adjusting the liquor filling machine, be sure to tighten the loose screws, and use the shake handle to turn the machine to check whether the action meets the requirements before driving.

4. Check whether the speed throttle valve and the filling interval throttle valve are closed, and the throttle valve cannot be closed. 5. Check if there is any foreign matter in the quick-installation three-way control valve. If there is any foreign matter, check it out immediately; check if there is air in the quick-installation three-way control valve and the skin tube of the filling head. If there is air, try to reduce or reduce the air. remove.

6. Check whether all the sealing rings are damaged. If they are damaged, please replace them with new ones.

7. Check whether the valve core of the filling nozzle has jamming or delayed opening. If there is a jam, install the valve core from the beginning. If the opening is delayed, the throttle valve of the thin cylinder needs to be adjusted.

8. Check whether the filling speed of the wine filling machine is too fast, adjust the filling speed throttle valve, and reduce the filling speed.

简体中文

简体中文 English

English