Many people do not know whether to choose a fully automatic filling machine or a semi-automatic filling machine when choosing a filling machine. In fact, the difference between a fully automatic and a semi-automatic filling machine lies in the beer can sealing machine following two points:

1. The degree of automation is different. The degree of automation of the fully automatic filling machine is high, and the filling speed is faster. The filling speed of the semi-automatic filling machine is relatively slow and requires manual assistance.

2. In terms of price, semi-automatic is cheaper than fully automatic

The following is a detailed introduction to the liquid filling machine.

The semi-automatic liquid filling machine adopts a single-head plunger type quantitative filling device. The machine realizes the quantitative supply of materials by adjusting the distance of the plunger movement, and at the same time makes arbitrary adjustments according to different filling amounts within the measurement range. It is easy to operate and quantitatively discharge. And it has the characteristics of accurate measurement and simple structure. It is made of stainless steel and meets the hygienic requirements of food and medicine production. Widely used, it is suitable for quantitative filling of paste and liquid in daily chemical, pharmaceutical, food, chemical and other industries.

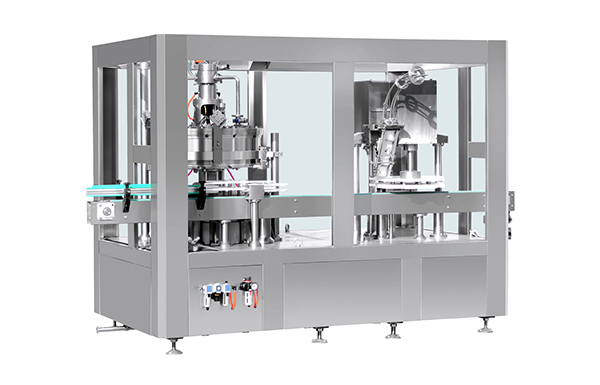

The automatic liquid filling machine is improved on the basis of the original series of filling machine products, and some additional functions have been added. Make the product more simple and convenient in operation, precision error, installation adjustment, equipment cleaning, maintenance and so on. It is widely used in various industries such as daily chemical and oil, and can fill different high viscosity fluids. The machine has compact and reasonable design, simple and beautiful appearance, and convenient adjustment of filling volume.

For manufacturers with high automation requirements and large output, fully automatic filling machines are undoubtedly more suitable, and for small and medium-sized manufacturers, semi-automatic filling machines are also a good choice. This mainly depends on the choice of the producer.

简体中文

简体中文 English

English